Extreme environments. Exceptional control.

Downtime is expensive and safety is non‑negotiable. Traxia gives you live machine intelligence, anomaly alerts, and satellite‑ready connectivity to keep operations productive across pits, plants, and off‑road terrain.

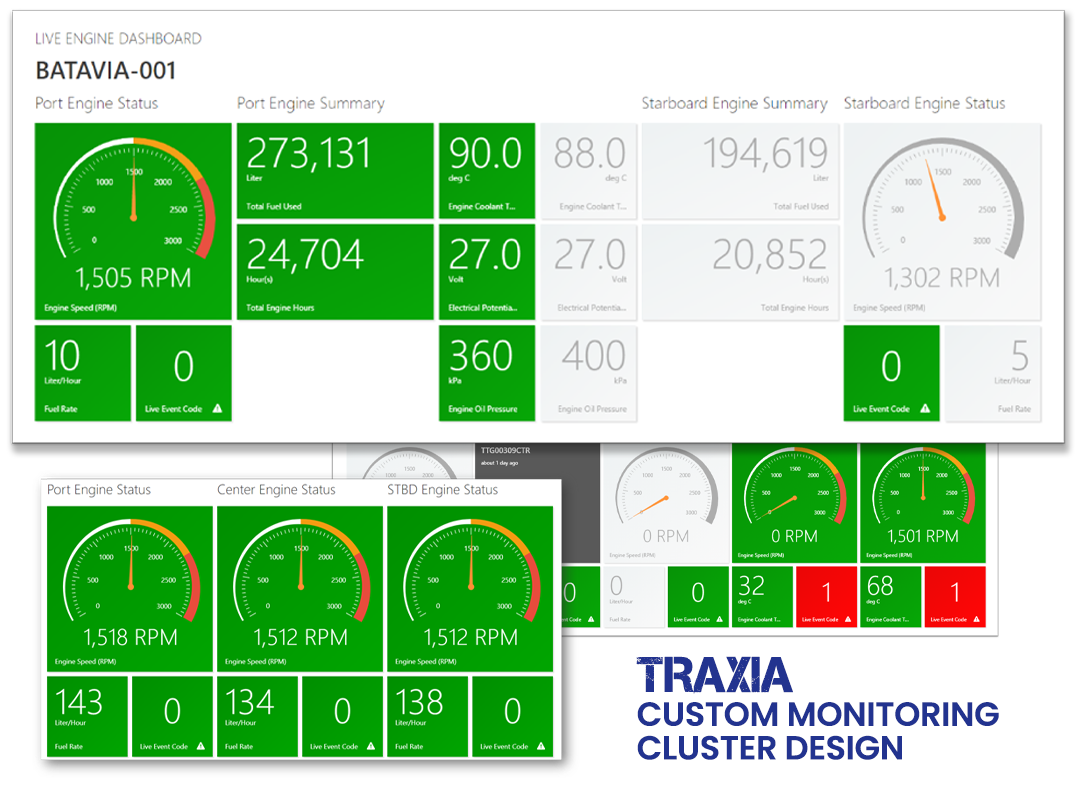

Track utilization, fuel, and component health in one view. Detect issues early, schedule maintenance precisely, and prove compliance with export‑ready reports.